In the world of manufacturing, the precision of a balanced spindle is everything. Whether you’re running a high-speed CNC machine, a grinding spindle, or a complex production line, even the slightest imbalance in a spindle can cause significant problems. Vibration, noise, reduced performance, and increased wear are just some of the issues caused by imbalance. That’s why using a high-quality tool like a Balmac Balancer to balance spindles is a game-changer for machine operators and facility managers alike.

What Does a Balanced Spindle Mean?

A balanced spindle operates smoothly, without unnecessary vibrations or uneven rotations. Balancing ensures that the spindle’s weight is evenly distributed around its rotational axis, which prevents wobbling during operation. When spindles are imbalanced, the result can be misaligned cuts, inconsistent machining, and damage to both the spindle and the equipment it powers.

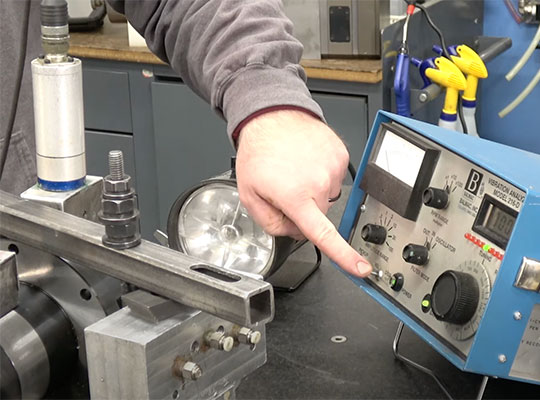

The Balmac Balancer is designed to measure and correct imbalance with unmatched precision. By addressing imbalance issues early, this tool not only helps maintain peak machine performance but also extends the life of your spindle and other critical components.

The Benefits of a Balanced Spindle

- Improved Precision and Quality

- Reduced Vibration and Noise

- Increased Spindle Lifespan

- Enhanced Machine Efficiency

- Prevention of Costly Downtime

How Does a Balmac Balancer Work?

The Balmac Balancer measures vibration levels and identifies the imbalance within a spindle. Once the imbalance is located, operators can add or adjust weights, align components, or make other necessary modifications to correct the issue. The process is fast, efficient, and can be applied to spindles across a wide range of machines and industries.

Why Spindle Balancing Matters

Balancing isn’t just about making machines run smoother—it’s about protecting your investment. Modern manufacturing relies on precision equipment that requires careful maintenance to perform at its best. Neglecting spindle balance can lead to costly repairs, lost production time, and subpar results. The Balmac Balancer helps you stay ahead of these problems, ensuring that your machines operate reliably and consistently.

Invest in Your Productivity

If your facility depends on high-performance machining or manufacturing equipment, spindle maintenance should be a regular part of your maintenance routine. In the event that your spindle does need repair or rebuilding, SPS has the trained spindle repair technicians and customer support staff to meet your needs and get you back up and running quickly.

Learn more about spindle repairs here.

Watch the SPS video on Balmac Balancing here.